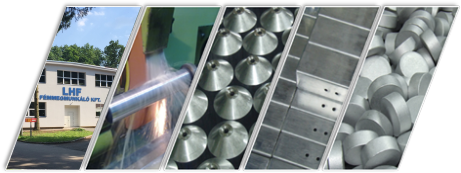

LHF Kft. Aluminium and copper impact extrusions and deep drawing

The LHF Fémmegmunkáló Kft specialized in the production of aluminium and copper impact extruded components for more than two and half decades. The major - aluminium impact extrusion - technology was extended at our company with deep drawing and stamping with the common raw materials of these technologies such as aluminium, copper, steel, stainless steel, Viton and Teflon. Additionally we can apply the following surface treatment technologies in house: tumbling, sand blasting, degreasing and white yellow and black zinc-plating.

The main strength of the Company lies in its capability to combine the different technologies (such as impact extrusion, deep drawing, stamping, punching forging, zinc-plating); to produce our own tools; to react quickly to our customers request; to be able to produce small and large volumes; to offer wide range of additional services; to have the willingness for the continuously improvement of our processes; to offer high quality products at a competitive price.. We have the knowledge and experience to design and develop cold forming tools, as well as the capacity to produce them within our own tool room.

The impact extrusion and the deep drawing technologies are offering in many cases a more cost-effective solution of producing aluminium and copper components comparing to other technologies even at a relatively small (1 000 pieces) volumes. The customers of LHF are enabled to achieve economy of manufacture by combining several cold forming technologies to be carried out under one roof, with the required expertise.

Our deep-drawn and stamped components can be zinc-plated/treated in our surface treatment facility according to our customer’s requirements, also we are in position to test the products in our own salt spray chamber. Our degreasing and zinc-plating machines provide a wide range of surface treatment possibilities such as white (blue/colorless), yellow and black zinc-plating, while providing continuous control over production.

We are offering our free capacity of these services and machines for our existing and potential customers. If you have any question, please do not hesitate to contact us.