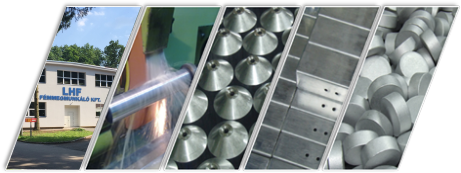

Stamping

The shapes of the blanked and stamped components are arbitrary, produced usually with mechanical presses by shearing. The form of the stamped material usually sheet or strip but it can be a deep drawn or impact extruded component as well. The stamping and blanking technologies might be cost effective solution for the production of aluminium, steel, stainless steel, copper, viton and from other raw materials comparing to other technologies. The investment in the tooling might return even at small (1-2 000 pieces) volumes.

The stamping and blanking are such a cold forming technologies where the only difference between them is that the falling out or the remaining part is the product.

To ensure the dimension shape and the cutting quality the active tools are hold in die sets.

Advantages particularly associated with the stamping process:

- Wide range of raw materials

- Economy of manufacture achieved through minimum material and energy usage

- Rapid production rate

- Tight tolerances during the production

- Relatively low tooling cost

Machines of the stamping technology:

Generally used machine for stamping (blanking, punching piercing) are eccentric and the hydraulic presses. The capacities of our presses are vary between 5 to 250 tons.